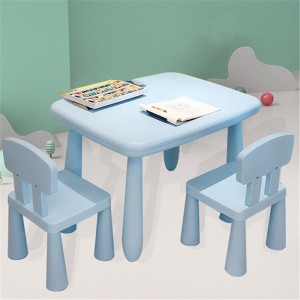

Ukufutha Izibunjwa Zethebula Lepulasitiki Nesihlalo

Incazelo Yomkhiqizo

I-All star plast iyakwazi ukuhlinzeka ngezixazululo zobuchwepheshe ezibanzi nezididiyelwe zezinhlobonhlobo zezicelo zokubumba igalelo kuzo zonke izimboni eziningi okuhlanganisa nesipiliyoni seminyaka engaphezu kwe-15 emikhiqizweni yepulasitiki ebunjiwe. Ithimba lethu labanolwazi liqeqeshiwe futhi linelayisensi yokwenza imibese eyimishini yobunjiniyela engakwazi ukusika noma ukusika ingxenye ngesikhathi somjikelezo wokubumba. Lezi zixazululo zihlanganisa ama-blade ahlehlisayo aklanywe ngonjiniyela, izinto eziyinkimbinkimbi zokuhlehlisa ukuhlehliswa, izindlela ezingasika izimbobo engxenyeni phakathi nomjikelezo wokubumba, izisetshenziswa zokunciphisa izingxenye ezihlanganiswe nesikhunta, nezindlela eziyinhloko. Zonke lezi zixazululo zisiza ukunikeza ukuguquguquka komklamo womkhiqizo.

Uma kuqhathaniswa nezihlalo ezikhiqizwe ukubunjwa komjovo, izihlalo ezenziwe nge-extrusion blow molding zinezinzuzo ezilandelayo:

1. Izindleko zemishini yokubumba i- blow, ikakhulukazi isikhunta sokushaywa, ziphansi. Lapho ubumba imikhiqizo efanayo, izindleko zemishini yokubumba icishe ibe yi-1/3 yaleyo yemishini yokujova, kanti nezindleko zokukhiqiza imikhiqizo nazo ziphansi.

2. Enkambweni yokubumba isihlalo, i-parison yesitulo isetshenziselwa ukwakha isihlalo sepulasitiki ngaphansi kwengcindezi ephansi ngekhanda lomshini, futhi ifakwe ngaphansi kwengcindezi ephansi. Umkhiqizo unengcindezi encane eyinsalela, ukumelana nokwelula, umthelela, nokuvikelwa kwemvelo. Ukusebenza kwezinhlobo ezahlukahlukene kuphezulu, futhi kunokusebenza okungcono. Lapho isihlalo sokubumba umjovo sibunjwa ngomjovo, ukuncibilika kufanele kudlule kumgijimi wesikhunta kanye nesango ngaphansi kwengcindezi ephezulu, okuzobangela ukusatshalaliswa kokucindezeleka okungalingani.

3. Isisindo samangqamuzana esihlobene sezinto zokusetshenziswa zepulasitiki ezibumba igalelo liphezulu kakhulu kunaleso samapulasitiki ebanga lomjovo. Ngakho-ke, isihlalo esenziwe nge-blow molding sinomthelela omkhulu wokuqina kanye nokumelana nokucindezeleka okuphezulu kwemvelo.

4. Njengoba isikhunta sokushaya sakhiwe kuphela isikhunta sesifazane, ubukhulu bodonga bomkhiqizo bungashintshwa ngokumane ulungise igebe phakathi kwe-die orifice of the die noma izimo ze-extrusion, okuzuzisa kakhulu emikhiqizweni engakwazi ukubala ngokunembile. ukuqina kodonga oludingekayo kusengaphambili. Izindleko zokushintsha ubukhulu bodonga bomkhiqizo wokubumba umjovo ziphakeme kakhulu.

5. Isihlalo esibunjwe ngokushaywa singakhiqiza isihlalo esiyinkimbinkimbi, esingavamile, ne-monolithic. Uma usebenzisa ukubumba komjovo, ngemva kokukhiqiza imikhiqizo emibili noma ngaphezulu, kufanele ihlanganiswe nokufakwa kwe-snap, i-solvent bonding, noma i-welding ye-ultrasonic.

Ukunemba kwezihlalo ezibunjwe ngokushaywa ngokuvamile akuphakeme kakhulu kunemikhiqizo ebunjiwe yomjovo; ukubukeka kwezihlalo ezibunjwe ngomjovo kuvame ukukhahlameza, okunqunywa izinqubo zabo ezihlukene. Mayelana nombuzo wokuthi yisiphi esingcono, isihlalo esibunjwe ngokushaywa, noma isihlalo esibunjwe ngomjovo, ngicabanga ukuthi kuya ngezidingo ezithile.